A precise wire-drawing die can be used to shape wires with precise dimensions that impart strength or conductivity. Therefore, proper identification and selection of a wire-drawing die manufacturer can help achieve the highest-quality wires with precise tolerances, high consistency, and minimal waste.

Key aspects manufacturers evaluate

• Ability to achieve micron-level accuracy

• Consistency across long production runs

• Tool durability and surface quality

• Application-specific engineering support

Wire drawing has moved far beyond basic size reduction. Modern applications demand exact dimensions, clean surfaces, and stable mechanical performance. As tolerances tighten, the role of a wire drawing die manufacturer becomes central to production success. Precision today decides whether the wire meets performance standards or fails during use.

Manufacturers usually begin with a simple need. The wire must meet exact specifications every time. From that point, the journey leads through tooling accuracy, engineering depth, and long-term reliability. Understanding this journey helps buyers make informed decisions with confidence.

Why are microns the new benchmark in wire drawing?

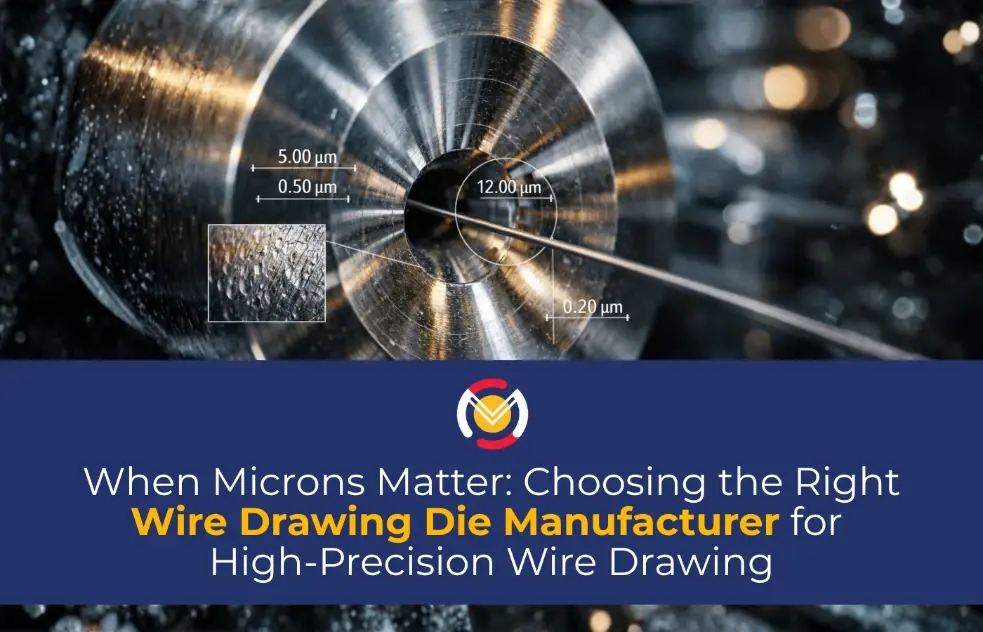

In wire drawing, micron-level control determines diameter consistency, roundness, and surface finish in every meter produced. Even small deviations may affect performance in demanding applications.

Industry tolerances continue to shrink as they evolve. A wire-drawing die manufacturer would have to design tooling that maintains accuracy at high speed and under high pressure and withstands constant use.

1. Diameter and roundness control: Small variations in die shape affect wire diameter and roundness. Unreliable control results in variation that cannot be completely eliminated in subsequent processing, particularly in precision or high-speed drawing.

2. Surface finish consistency: Die surface quality affects friction and drawing forces. Variations in surface finish affect surface quality, lubrication, and heat generation during drawing.

3. Influence on electrical and mechanical properties: Variations in dimensions alter conductivity and tensile properties. Reliable micron control ensures consistent performance in electrical and mechanical applications.

4. Cumulative tolerance effects: Small variations accumulate in multi-stage drawing operations. Precise control in the early stages of drawing reduces cumulative tolerance effects throughout the entire drawing process.

What role does tooling play in achieving micron-level accuracy?

Tooling controls how metal flows during wire drawing. Geometry directly determines the final wire size, surface quality, and material behavior. Without precise tooling, achieving stable tolerances becomes difficult.

A wire drawing die manufacturer focuses on tooling accuracy because every production outcome depends on it.

1. Die geometry and bearing control: Accurate profiles guide material reduction smoothly. Proper bearing length stabilizes final wire dimensions.

2. Surface finish inside the die: Smooth internal surfaces reduce friction and heat generation. Uniform contact supports consistent wire quality.

3. Load distribution during drawing: Balanced tooling design prevents uneven stress on the wire. Even load improves dimensional consistency.

4. Tool alignment and concentricity: Correct alignment ensures uniform material deformation. Concentric dies reduce ovality and surface defects.

How does precision engineering shape solutions from a wire drawing die manufacturer?

Precision engineering ensures that every die performs consistently from the first draw to the last. Engineering decisions affect durability, accuracy, and repeatability throughout the die’s lifecycle.

A wire drawing die manufacturer applies precision engineering to maintain tight tolerances across production batches.

1. Geometry and bearing design

The length of the bearing and approach angle has a direct effect on material flow and stability. Incorrect geometry will accelerate wear and increase diameter variation.

2. Surface condition and finish control

The internal surface finish affects friction and heat generation. Controlled polishing will minimize surface damage and ensure consistent drawing forces.

3. Material choice trade-offs

Tungsten carbide, PCD, and natural diamond offer different properties for wear and finish. The choice of material will depend on the wire material, speed, lubrication, and tool life.

4. Validation prior to use

Dimensional verification, concentricity inspection, and surface analysis are necessary to ensure that design specifications are met in the tooling prior to production.

Research on the friction and wear of tungsten carbide dies in dry wire drawing by MPDI shows that die material behaviour and surface interaction significantly affect tool life and wire consistency, highlighting the importance of controlled manufacturing processes.

What tooling solutions does a wire drawing die manufacturer offer for high-precision wire drawing?

Performance is determined by the retention of accuracy over time, rather than initial accuracy alone. Wear, friction, and material properties combine to drive long-term performance.

An awareness of these considerations can help avoid unwanted variation in manufacturing.

Wear processes in drawing

Friction between the wire and the die causes progressive material removal. Asymmetrical wear generates ovality and surface damage before catastrophic failure.

Heat and friction control

Drawing speed and cooling affect heat generation. Excessive heat promotes wear and alters material properties at the die interface.

Reconditioning and relapping life

Dies can be restored to their original geometry, but each reconditioning cycle impacts bearing length and performance parameters. Engineering experience defines useful life.

Uniformity in reconditioned tools

Reconditioned tools must perform to original specifications. Controlled relapping ensures predictable performance over multiple service lives.

How does a wire drawing die, manufacturer maintain consistency across speeds and volumes?

As production scales, maintaining accuracy becomes more challenging. Heat, friction, and continuous operation place stress on tooling. Consistency depends on stable die performance over time. A wire-drawing die manufacturer designs tooling that performs reliably across varying speeds and volumes.

1. Dimensional inspection techniques

Diameter, concentricity, and geometry are inspected using calibrated instruments. Inspection confirms that specifications are met, not assumed.

2. Surface assessment and finish inspection

Surface quality is inspected to identify micro-errors that affect friction and wear. Early identification prevents problems downstream.

3. Batch-to-batch consistency inspection

Each batch of production is inspected against established standards. Consistency ensures predictable performance with repeated orders.

4. Process correction and feedback

Inspection results provide feedback for manufacturing corrections. Ongoing correction ensures stability.

Which industries rely heavily on a precision wire-drawing die manufacturer?

Several industries depend heavily on accurate wire dimensions to ensure the quality of their output. In these industries, the quality of tooling affects the efficiency of the tools produced.

1. Automotive and electric vehicles: Wiring systems require uniform dimensions for safety and efficiency. Precision supports consistent electrical performance.

2. Electrical and industrial applications: Tight tolerances support insulation, conductivity, and durability. Consistent wire quality reduces field failures.

3. Specialty and fine wire manufacturing: Precision supports micro- and fine-wire production. Application accuracy defines end-use success.

4. Infrastructure and energy sectors: Stable wire dimensions support long-term reliability. Performance consistency reduces maintenance issues.

How does a buyer evaluate a wire drawing die manufacturer?

Buyers typically move through a structured evaluation process. The focus begins with performance needs and shifts toward reliability, support, and long-term value.

A wire drawing die manufacturer that understands this journey builds trust early.

1. Technical capability assessment: Ability to meet micron-level tolerances is essential. Experience across materials and wire sizes adds confidence.

2. Operational reliability: Consistent performance reduces production risk. Predictable tooling behavior supports long-term planning.

3. Engineering support: Guidance during selection improves outcomes. Support helps address application challenges.

4. Long-term partnership potential: Reliability matters beyond the first order. Consistency builds lasting supplier relationships.

How does Mikrotek support high-precision wire drawing requirements?

Mikrotek is a precision wire-drawing die supplier with years of experience in engineering and producing wire-drawing dies. Mikrotek provides wire-drawing dies engineered for precision, strength, and reliability. Mikrotek provides engineering discipline and manufacturing processes to support the needs of manufacturers whose performance is defined by tolerance. The emphasis is still on solid tooling with dependable results over long production runs.

Learn different diamond dies rovided by Mikrotek in this article

Diamond Dies for Wire Drawing: A Key to Precision and Efficiency

Conclusion

Precision in wire drawing begins with tooling decisions. A wire-drawing die manufacturer plays a key role in creating wire quality, stability, and efficiency in its production process, where, when microns count, precision engineering brings clarity to the process itself. Connect with Mikrotek to explore precision die solutions built for consistent wire performance.

FAQs

1. What does a wire drawing die manufacturer do?

A manufacturer designs and produces a wire-drawing die that controls the size, form, and finish of the wires. Precision manufacturing guarantees a consistent output with consistent tolerances.

2. What methods of accuracy must a wire drawing die manufacturer consider?

A wire-drawing die-making company achieves the desired level of accuracy through precise die design and manufacturing. Precise geometry, along with a smooth internal surface finish, helps achieve micron-level tolerances.

3. Why is Tooling Quality significant in Wire Drawing?

Tooling quality controls material flow and final wire sizes. A wire-drawing die producer that supplies high-precision tooling can minimize variation, increase yields, and deliver consistent-quality wires under various production conditions.

4. How can the buyer of wire-drawing dies decide on the manufacturer of the dies to be chosen ?

One should consider engineering abilities, tolerance capacity, application knowledge, and consistency when making the right choice for buyers. A trustworthy wire-drawing die manufacturing company helps maintain efficient production processes and systems.

5. How does a wire drawing die manufacturer support different industries?

A wire drawing die manufacturer supports industries by offering application-specific tooling solutions. Tailored designs help meet performance requirements in automotive, electrical, and industrial wire manufacturing.

6. How does a wire drawing die manufacturer improve long-term production efficiency?

By supplying dies that hold accuracy over repeated runs. Stable tooling reduces downtime, minimizes adjustments, and maintains consistent wire output across production cycles.