Diamond Die Working Equipment

One Stop Shop for Polishing Dies

Write to Us

For any questions or assistance, please reach out to us. We are here to help you!

Diamond Die Working Equipment - Wire Polishing Machines

These machines are designed and developed for resizing and repolishing of ND Dies, Polycrystalline, and SSCD Dies.

The diamond die working equipment are manufactured with high-precision engineering, high speed, individual controls, and wire tension adjustment. The oscillation of dies makes these machines extremely versatile and user-friendly.

We have different models, which include single and multiple spindles; the entire range of drawing dies varies from 0.010 to 30.00 mm. Follow

These machines are designed and developed for resizing and repolishing of ND Dies, Polycrystalline, and SSCD Dies.

The diamond die working equipment are manufactured with high-precision engineering, high speed, individual controls, and wire tension adjustment. The oscillation of dies makes these machines extremely versatile and user-friendly.

We have different models, which include single and multiple spindles; the entire range of drawing dies varies from 0.010 to 30.00 mm.

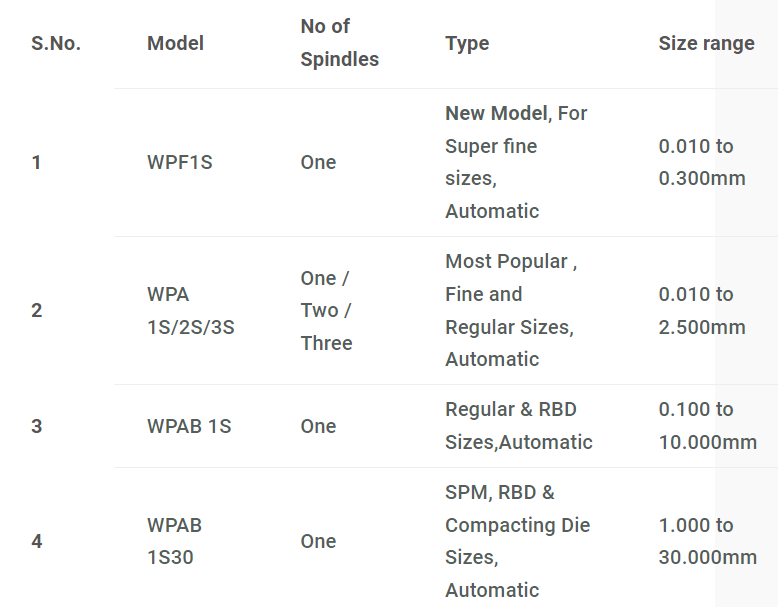

| S.No. | Model | No of Spindles | Type | Size range |

|---|---|---|---|---|

| 1 | WPF1S | One | New Model, For Super fine sizes, Automatic | 0.010 to 0.300mm |

| 2 | WPA 1S/2S/3S | One / Two / Three | Most Popular , Fine and Regular Sizes, Automatic | 0.010 to 2.500mm |

| 3 | WPAB 1S | One | Regular & RBD Sizes,Automatic | 0.100 to 10.000mm |

| 4 | WPAB 1S30 | One | SPM, RBD & Compacting Die Sizes, Automatic | 1.000 to 30.000mm |

Diamond Die Working Equipment - Ultrasonic Die Polishing Machines

Our diamond die working equipment are designed and developed to work, and polish reduction angles of polycrystalline, SSCD, and natural diamond dies.

The USBNG model is supplied with an inbuilt needle grinder to produce accurate angles with ease repeatedly. The feedback ultrasonic generator is matched with a sandwich-type piezoelectric crystal head to give fine continuous ultrasonic power.

The combination of an inbuilt needle grinder and feedback ultrasonic generator ensures accurate profile and polishing of diamond dies in the quickest way.

Our USMBT models are provided with an external bench needle grinder.

We also offer on-the-job training to die technicians to master the art of making right quality dies.

We have different models to cover the entire range from 0.010 to 30.00 mm.

Our diamond die working equipment are designed and developed to work, and polish reduction angles of polycrystalline, SSCD, and natural diamond dies.

The USBNG model is supplied with an inbuilt needle grinder to produce accurate angles with ease repeatedly. The feedback ultrasonic generator is matched with a sandwich-type piezoelectric crystal head to give fine continuous ultrasonic power.

The combination of an inbuilt needle grinder and feedback ultrasonic generator ensures accurate profile and polishing of diamond dies in the quickest way.

Our USMBT models are provided with an external bench needle grinder.

We also offer on-the-job training to die technicians to master the art of making right quality dies.

We have different models to cover the entire range from 0.010 to 30.00 mm.

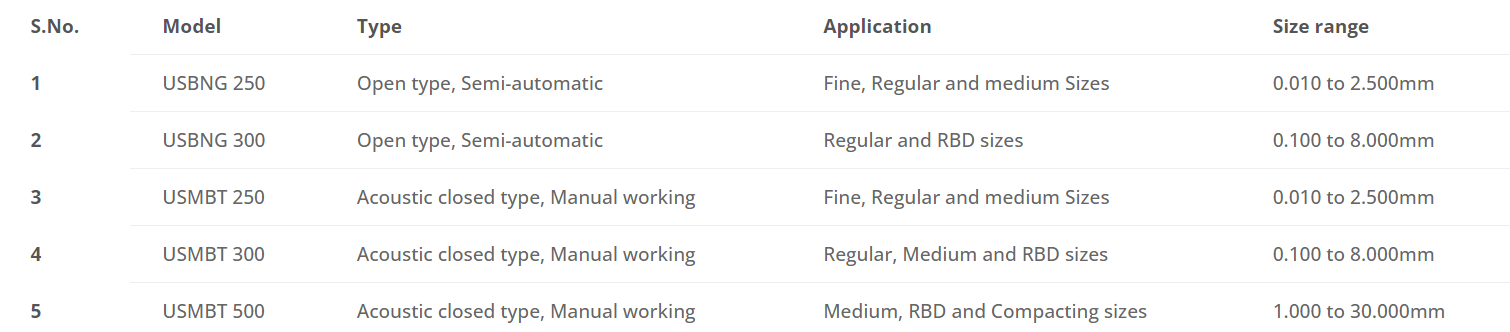

| S.No. | Model | Type | Application | Size range |

|---|---|---|---|---|

| 1 | USBNG 250 | Open type, Semi-automatic | Fine, Regular and medium Sizes | 0.010 to 2.500mm |

| 2 | USBNG 300 | Open type, Semi-automatic | Regular and RBD sizes | 0.100 to 8.000mm |

| 3 | USMBT 250 | Acoustic closed type, Manual working | Fine, Regular and medium Sizes | 0.010 to 2.500mm |

| 4 | USMBT 300 | Acoustic closed type, Manual working | Regular, Medium and RBD sizes | 0.100 to 8.000mm |

| 5 | USMBT 500 | Acoustic closed type, Manual working | Medium, RBD and Compacting sizes | 1.000 to 30.000mm |