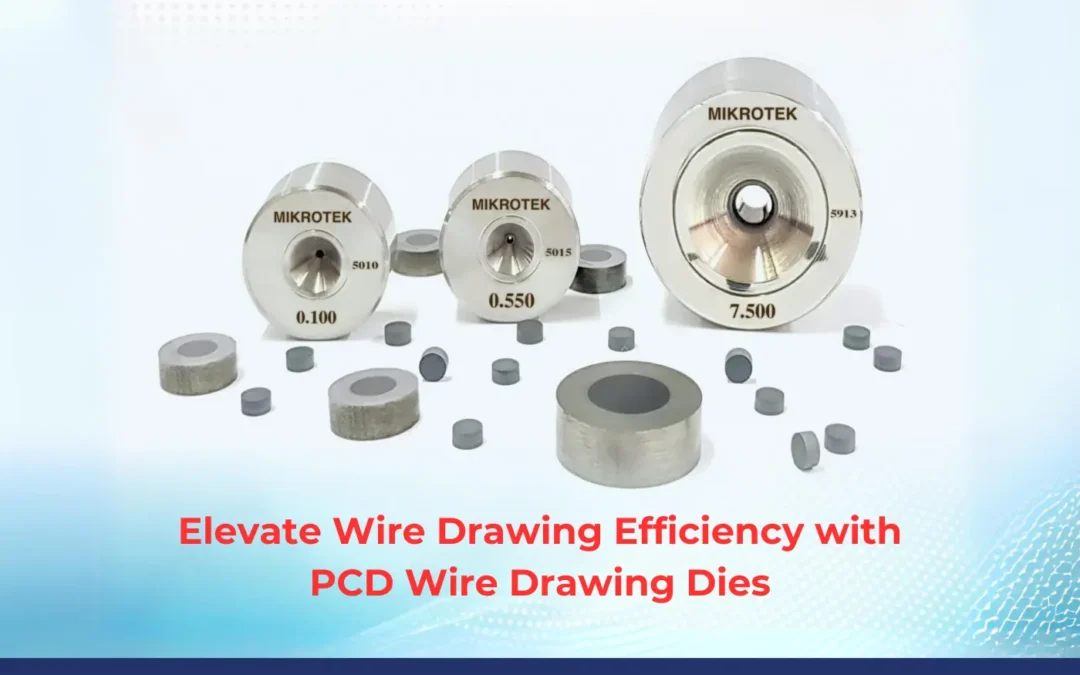

What are PCD Wire Drawing Dies?

PCD Drawing wires are tools used to reduce metal wires’ diameters with high precision. They provide remarkable hardness, wear resistance, and durability. These wires are the better choice for drawing non-ferrous metals like copper and aluminium, resulting in tight tolerances and smooth finishes. PCD wire drawing dies are predominantly used in high-quality wire production industries such as electronics and automotive.

What are PCD Wire Drawing Dies?

PCD Drawing wires are tools used to reduce metal wires’ diameters with high precision. They provide remarkable hardness, wear resistance, and durability. These wires are the better choice for drawing non-ferrous metals like copper and aluminium, resulting in tight tolerances and smooth finishes. PCD wire drawing dies are predominantly used in high-quality wire production industries such as electronics and automotive.

Polycrystalline diamond dies are used to produce stainless steel, medical wires, low and high-carbon steel, welding wire, copper and aluminium conductors, magnets, EDM tungsten, molybdenum, coated and alloy wires, and more.

There are certain factors to consider while choosing PCD wire drawing dies.

Factors to consider when choosing PCD wire drawing dies:

Wire drawing is a process that involves pushing a wire through a series of dies to reduce its diameter. It is essential for manufacturing electrical wiring, cables, and springs. Choosing the right dies involves considering several factors.

This blog will discuss these factors and emphasize the importance of PCD wire drawing dies.

Material Composition:

It is crucial to select wire drawing dies with the correct material composition when choosing them. They are widely known for their hardness and abrasion resistance, which makes them essential for high-speed wire drawing operations. These characteristics enhance the effectiveness of the wire drawing process.

Die Design: One of the crucial factors that is key in drawing dies is the design. It impacts the quality and accuracy of the wire drawing process. PCD wire drawing dies are known for their durability and superior wear resistance. It expands the die’s lifespan and improves the efficiency of the wire drawing process. While choosing PCD wire drawing dies, it is essential to ensure that the design meets the specific needs of the drawing process.

Cost: Cost plays a vital role in choosing tools for the operation. Though PCD wire drawing dies have higher initial costs than other types, they provide significant long-term savings. Their durability decreases maintenance and replacement costs over time. When assessing the cost of PCD wire drawing dies, balancing the initial investment against the long-term benefits they provide is essential.

Performance: Performance is the main factor to consider. PCD wire drawing dies are known for high performance, which improves the quality and efficiency of the wire drawing process. It is also essential to evaluate the specific requirements of the drawing process and ensure the dies meet the desired standards. Choosing high-quality PCD wire drawing dies ensures that the drawing operations run efficiently.

Below are the advantages offered by PCD wire drawing dies:

Retention of Roundness for a Long Time:

PCD wire drawing dies retain their perfect shape and dimensions even after prolonged usage. This ensures high-quality wire production, decreasing the frequency of die replacements and reducing production interruptions.

Less Downtime of Drawing Machine:

The PCD wire drawing dies have exceptional resilience and wear resistance, which reduces maintenance requirements and less frequent die replacements, enhancing operational effectiveness and productivity.

Suitable for Both Wet and Dry Drawing:

PCD wire drawing dies are diverse and function effectively in wet and dry environments. This versatility enables manufacturers to utilize them across multiple drawing operations, streamlining operations and minimizing costs.

Suitable for Cold and Hot Drawing:

The dies endure the pressure of both hot and cold drawing processes. Their resistance to different temperatures ensures stable performance and endurance, making them an ideal choice for multiple manufacturing conditions.

Conclusion:

PCD (Polycrystalline Diamond) wire drawing dies are vital tools in the wire drawing industry, offering exceptional hardness, wear resistance, and longevity. These attributes make them ideal for high-precision applications across various metals, ensuring high-quality production with minimal maintenance. By investing in high-quality, manufacturers can enhance productivity, reduce downtime, and maintain a competitive edge in the market.