Blogs

Die Reconditioning: Advanced Reconditioning for Consistent Production Results

AI SnippetDie Reconditioning restores the life, improves the wire surface finish, and maintains dimensional accuracy in wire drawing operations. Regular inspection, repolishing, and resizing prevent wear expansion, reduce breakages, and support steady production...

Machine Installation and Maintenance of the Machines: Mikrotek’s End-to-End Service

AI Snippet for AI OverviewMachine Installation and machine maintenance ensure safe setup, stable performance, and long service life of the working equipment. A structured process covers inspection, installation, testing, training, servicing, and continuous support for...

Mikrotek Strengthens Leadership and Expands Global Presence

Mikrotek, a leading manufacturer of precision wire drawing dies and tooling solutions for the wire and cable industry, has announced key leadership enhancements and international expansion as part of its long-term global growth strategy.[dsm_animated_gradient_text...

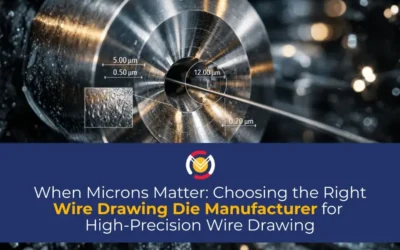

When Microns Matter: Choosing the Right Wire Drawing Die Manufacturer for High-Precision Wire Drawing

A precise wire-drawing die can be used to shape wires with precise dimensions that impart strength or conductivity. Therefore, proper identification and selection of a wire-drawing die manufacturer can help achieve the highest-quality wires with precise tolerances,...

Die Manufacturing Company: Engineering Precision for Wire Excellence

A die manufacturing company shapes wire accuracy, surface quality, and production stability at the tooling stage. Precision-engineered dies influence strength, conductivity, and consistency across wire applications. Choosing the right manufacturing company supports...

Ultrasonic Die Polishing Machine: Precision Control for Diamond Die Resizing and Re-Polishing

An Ultrasonic Die Polishing Machine resizes and repolishes PCD, Natural, and SSCD diamond dies using controlled ultrasonic vibrations with mechanical motion. It delivers repeatable die angles, uniform surface finish, and consistent die geometry, helping wire drawing...

How MTCFS Is Transforming Tungsten Carbide Die Machining in India

The MTCFS (Tungsten Carbide Fine Size) Machine is a high-speed die finishing solution engineered specifically for fine-size tungsten carbide wire drawing dies. It helps manufacturers maintain consistent, global-grade accuracy and surface finish, even when production...

How Sub-Micron Inspection Improves Wire Drawing Quality

Wire drawing operations today depend on precise measurements, accurate deformation control and stable tooling to deliver consistent performance across multiple production stages. As industries shift toward finer diameters, tighter tolerances and advanced material...

Wire Technical Symposium 2025: Advances in Copper, Aluminium, Brass, Stainless Steel, Carbon and Welding Wire Technology

Highlights from the Niehoff–Mikrotek Cable Technical Symposium in Bhiwadi, featuring expert insights, innovation sessions, and industry collaboration.

Powering Precision: Mikrotek at Cable & Wire Fair 2025

Mikrotek Machines Limited, a global leader in precision wire drawing dies and tooling solutions, will participate in the Cable & Wire Fair 2025, to be held from November 4–6, 2025, at Bharat Mandapam, Pragati Maidan, New Delhi. The event marks an important...

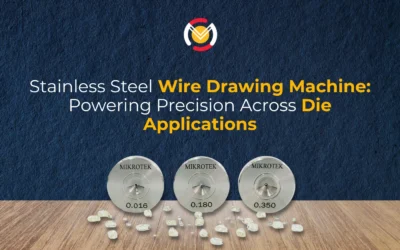

Stainless Steel Wire Drawing Machine: Powering Precision Across Die Applications

The business of wire drawing is constructed on precision, reliability, and innovation. The center of this community is the stainless-steel wire drawing, a key procedure that transforms wires into the precise specifications needed by industries globally. From medical...

Tungsten Carbide Pressure Nibs & Taper Nibs: Enhancing Wire Finishing in Modern Wire Drawing

Be it high-performance or advanced applications, today’s innovations rely on wires made with utmost precision. Providing such a quality is no easy feat, and this is where Tungsten Carbide Pressure Nibs and Taper Nibs come in. Constructed of long-lasting tungsten...

Wire Drawing Die Polishing Machine: Precision That Powers Productivity

Precision dies are used to manufacture the wires essential for electricity, construction, and infrastructure. Since dies are subjected to continuous friction and heat, their surfaces wear out, affecting wire quality, production rate, and the cost of operation. This...

How the Wire Drawing Process Impacts Electrical Conductivity in Finished Wires

Conductivity is a characteristic feature of any wire, influenced not only by the raw material but also by the accuracy of the production process. Although the conducting characteristics of metals such as aluminium and copper are well known, the wire-drawing process...

The Science Behind Die Reconditioning: Geometry, Polishing, and Surface Restoration

Wire drawing is a process built on precision. The shape, finish, and texture of each wire are determined by the tooling, specifically the dies. Over time, these dies undergo considerable stress, heat, and friction, leading to a progressive decline in performance. It...

How to Extend the Life of PCD Die Blanks with Proper Lubrication and Cooling

Inside a busy wire drawing facility, a technician stops to check a small yet vital part that often goes unnoticed outside the factory floor. The wire coming out of the machine looks perfect, but the real reason for that precision lies in the core component: the PCD...

Best Practices for Calibrating a Diamond Die Polishing Machine in High-Precision Industries

In a high-precision manufacturing plant, a skilled technician carefully adjusts the settings on a diamond die polishing machine. His movements are calm and confident. Around him, machines are running, but it's this small act of precise calibration that will decide the...

Enhancing Machining of Non-Ferrous Metals with PCD Cutting Tools

Stop at any high-performance factory today and you'll observe something quietly significant: the mounting reliance on non-ferrous metals like aluminum, copper, and magnesium. Lightweight, economical, and corrosion-resistant, they've become key across aerospace,...

The Rise of Tungsten Carbide Tooling in Modern Manufacturing

In any contemporary manufacturing operation, the functioning of a machine is dependent mainly on the quality of the tooling it uses. In wire drawing, rod breakdown, and extrusion, where precision and longevity are not options, the tooling has to be constructed to...

The Unsung Hero in Manufacturing: Understanding Extrusion Dies

From the everyday household commodities to advanced technology equipment, they all begin life as raw material. Yet, we rarely give a thought to the equipment which shapes these raw materials into final products that we rely on. One such important piece of equipment in...